| |

By Angie DeRosa

CONFERENCE PRODUCER

Published: July 31, 2013 4:10 pm ET

Image By: Resysta North America

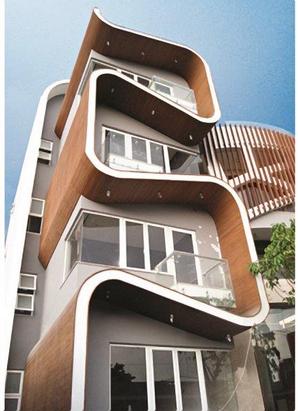

The facade of this building in Vietnam uses Resysta's vinyl products, which allow architectural flexibility and replicate the look of wood

DENVER — Plastics processors want to get the attention of architects, and plenty of construction products suppliers were on hand at the American Institute of Architects Convention, held June 19-22 at the Colorado Convention Center in Denver.

Although the event largely was focused on commercial construction, residential crept its way in, too, and both segments hold opportunity for suppliers and converters.

Total U.S. construction starts in 2013 are expected to rise 6 percent, according to the 2013 Dodge Construction Outlook. That same report predicted that single-family housing would grow 21 percent in units to 615,000. Multifamily housing will rise 14 percent to 285,000 units; and commercial building will increase 12 percent to 419 million square feet.

Still, the adjustment will be a "new normal." Builders and the supply chain are struggling with price sensitivity, price compression and margin compression. One source said that vinyl siding sales were down as much as 18 percent in May vs. the year-ago period and that sales were down 6 percent for the year to date. Expandable polystyrene resin manufacturers experienced their worst first quarter since 2009.

In housing activity, foreclosures in single-family homes have been easing, home prices are stabilizing and anyone who has purchased a home in the last year likely has benefited from low mortgage rates. Houses also are getting smaller. If a family might have lived in a 3,500-square-foot home, now that family might be more likely to want a 2,000-square-foot space.

"Directionally, it's good," said Pat Culpepper, president of Progressive Foam Technologies Inc., in Beach City, Ohio. "But the oxygen is not on. Do not take off your mask or you will suffocate."

Indeed, it's the "proceed with caution" mindset that was being espoused in the exhibit hall but supported by the idea that plastics technologies will grow in this stabilizing market.

One mechanical contractor who was representing the Radiant Professionals Alliance said he had to be convinced of the benefits of cross-linked polyethylene tubing for radiant floor heating years ago. Now, it is the primary material he uses, and he expects plastics technologies will continue to grow in building and construction.

BASF Corp. of Florham Park, N.J., was demonstrating its closed-cell spray polyurethane foam insulation, while DaVinci Roofscapes LLC of Kansas City, Kan., was touting the benefits of injection molded roof panels that replicate the appearance of wood shake.

DaVinci said the panels help builders achieve sustainability goals — a popular feature, since architects and builders are under pressure to improve energy efficiency and account for life-cycle analysis preferences.

DaVinci uses a proprietary polymer blend in molding the panels.

Elsewhere in the exhibit hall, PVC had its own cheerleaders. Several officials were focusing on the material's recyclability, durability and safety.

"The architects like our product," said Arne Zenneck, head of sales for Resysta North America Inc. of Chino, Calif., which sells profiles extruded from a combination of 40 percent PVC, 25 percent rice hulls, 20 percent calcium carbonate and 10 percent additives.

Resysta claimed a prime spot in the exhibit hall within the wood section. The product is making its way in the North American market, where customers include Starbucks Coffee Co. and P.F. Chang's China Bistro Inc.

Recently, the company was awarded a coveted Red Dot Product Design Award for its applications in the marine industry. The profiles are being used in exterior and interior installations, including decking, façades and furniture.

"Wherever they spec wood or tropical hardwoods, we want them to spec our product," Zenneck said. "We really try to replicate the wood look and the market we are after is tropical hardwoods. Although we have to admit that we are vinyl."

When an architect in Vietnam wanted to spec wood for a façade, Resysta officials talked him into using Resysta instead.

At the booth for the Alexandria, Va.-based Vinyl Institute, profiles from Resysta were placed side-by-side to create the blue, orange and green flooring to brand the booth. Communicating the virtues of vinyl in building and construction has been a difficult process, VI officials said.

What potential users need to hear is the sustainability aspects of vinyl, including the recyclability.

The goal for the inventor of Resysta was to make a greener vinyl. The inventor is from Singapore and his family runs PVC extrusion operations.

In the world of polyurethanes, Carter Millwork Flexible Molding of Linwood, N.C., was showcasing its architectural flexible molding that replicates the look of wood. Education is the focus for officials there.

"The bottom line is, we're chemistry," said David Welborn, vice president of sales, in a June 21 interview at Carter's booth. "It's all about awareness and education." | |